Storz Fittings

In the realm of firefighting and fluid transport, the importance of reliable and efficient fire department connections cannot be overstated. Storz fittings, a type of quick-connect coupling system, have emerged as a key asset for the fire protection industry.

History

Storz fittings were invented by Carl August Guido Storz in 1882. The fittings became standard in Europe and eventually gained acceptance in the U.S. In 1993 the National Fire Protection Association (NFPA) standardized the 4-inch (100 mm) and 5-inch (125 mm) Storz adapters with the adoption of NFPA standard 1963. These are the only sizes of Storz fittings standardized by the NFPA currently. NFPA is in the process of creating a new set of standards which consolidates NFPA standards 1931, 1936, 1961, 1963, and 1964 into one document. This new document, NFPA 1960, is in the approval process which will adopt 6-inch (150 mm) Storz, as well.

What is a Storz Fitting?

A Storz connection is a universal threadless quick connection traditionally used with large diameter hose for fire suppression and industrial fluid transfer. Municipal fire departments use Storz fittings as an alternative to the traditional threaded connection methods to quickly connect to fire hydrants and fire department connections. This solves the problem of mismatching couplings because of different thread types. Threads may vary from city to city, but all Storz 4-inch and 5-inch connections are the same in every location around the world.

How Does a Storz Connection Work?

To use a Storz fitting, the couplings are pressed together so the hooked lugs are mated into opposite flanges. Then, the couplings are rotated until fully latched to create a watertight seal. Most 4-inch and 5-inch Storz connections cannot be disconnected without releasing the latch.

Benefits of a Storz Connection

The main benefit of using a Storz connection is that NFPA-standardized connections will match with other Storz fittings of the same size. In addition, using a Storz fitting reduces connection time. While a threaded connection typically takes several turns to complete the connection, a Storz fitting only requires a quarter turn to connect. Eliminating compatibility issues and reducing connection time is paramount when lives and property are at risk during a fire.

Storz Fittings Applications

Storz fittings are commonly used in firefighting scenarios because of their quick connection which allows the rapid deployment of hoses and other tools during emergencies. However, Storz fittings can also be used in other applications. In industrial settings, Storz fittings facilitate the transfer of liquids, solids, and gases, ensuring a reliable connection. Additionally, municipalities often rely on Storz fittings for their water supply systems, as they provide a quick solution for connecting hoses and pipes during maintenance or emergency situations.

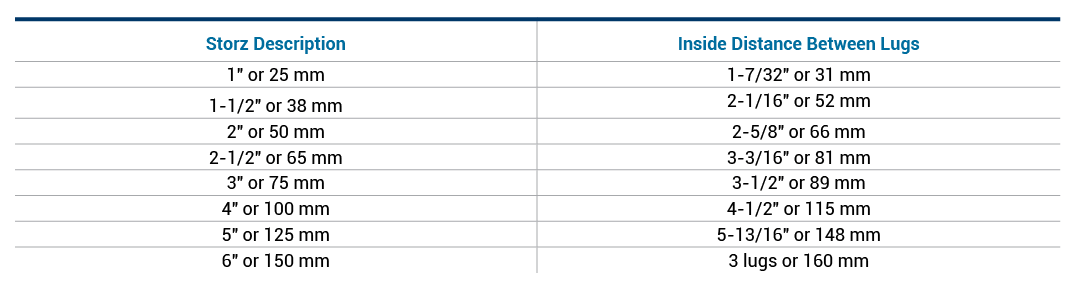

Storz Measurement

Storz fittings are measured by the inside distance between lugs. The measurement corresponds with a Storz description as depicted in the chart below.

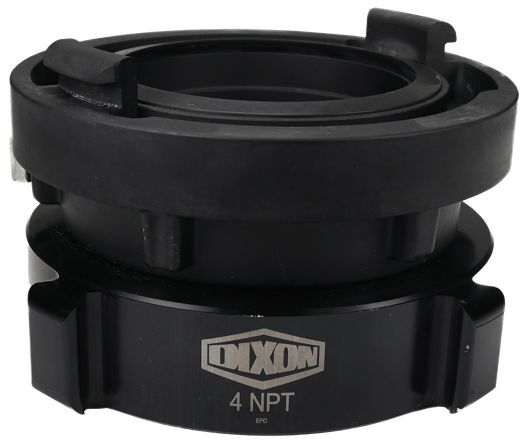

Dixon Storz Fittings

Dixon offers a variety of Storz fittings to ensure you always have The Right Connection® for your application.

Application:

- Fluid transfer not for petroleum or corrosive fluids

- Rigid adapter to jump between Storz sizes

Specification:

- Working pressure: 150 PSI at 70°F (21°C)

Approval:

- 4”, 5”, and 6” nominal components are anodized per MIL-A-8625 Type III Class 2

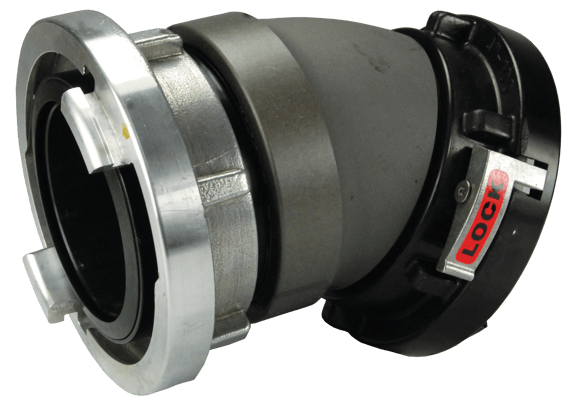

Application:

- Fluid transfer not for petroleum or corrosive fluids

- 30° elbow adapter to reduce stress on hose connections

Specification:

- Working pressure: 150 PSI at 70°F (21°C)

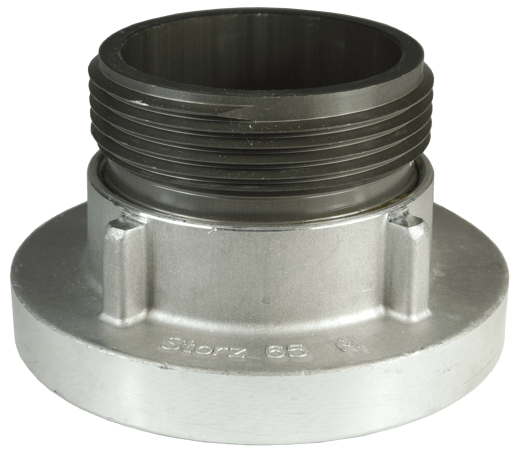

Application:

- Fluid transfer not for petroleum or corrosive fluid

- Rigid adapter to adapt a male threaded connection to Storz

Specification:

- Working pressure: 150 PSI at 70°F (21°C)

Approval

- Anodized components per MIL-A-8625 Type III Class 1

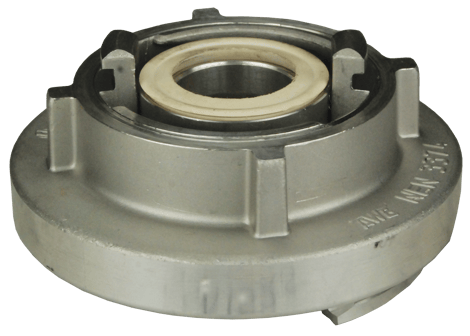

Application:

- Fluid transfer not for petroleum or corrosive fluids

- Swivel adapter to adapt a male threaded connection to Storz

Specification:

- Working pressure: 150 PSI at 70°F (21°C)

Approval:

- Anodized components per MIL-A-8625 Type III Class 1

Application:

- Fluid transfer not for petroleum or corrosive fluids

- Rigid adapter to adapt a female threaded connection to Storz

Construction:

- Machined from forged 6061 – T6 aluminum

Application:

- Fluid transfer not for petroleum or corrosive fluids

- Swivel adapter to adapt a male threaded connection to Storz while fully connected

Features:

- Continuous swivel

- Working pressure: 200 PSI at 70°F (21°C)

- Optional configurations from 2-1/2” to 6” on the non-Storz side

Application:

- Fluid transfer for petroleum or corrosive fluids

- Fire department connection for auto-sprinkler, standpipe, or dry hydrant systems

Feature:

- Screened connection

Approval:

- UL-approved

Application:

- Fluid transfer not for petroleum or corrosive fluids

- Fire department connection for auto-sprinkler, standpipe, or dry hydrant systems

Approval:

- UL listed

Summary

The symmetrical design and interchangeable nature of Storz fittings enhance their versatility. Incidents like the Baltimore fire of 1904 are a great example of why having matching threads is important and how the city could have benefitted from a Storz fitting.