Cam & Groove Comparison

In a previous blog post, we took a look into Dixon® cam & groove couplings. Now that we have an understanding of cam & groove functionality, materials, applications, configurations, and sizes, it is time to compare the different types of cam & groove couplings Dixon offers.

Dixon Cam & Groove

Dixon’s cam & groove couplings are precision machined to rigid tolerances. The durable stainless steel cam arm pins will not rust or bind, providing greater strength and safety. A recess holds the gasket firmly in place to ensure proper placement. The shank design allows for proper banding or crimping, thus eliminating the major cause of hose damage.

Boss-Lock Cam & Groove

Boss-Lock cam & groove patented safety feature allows safety clips to be attached once the lugs are passed through slots in the special cam lever arms. The pull-ring safety clip simplifies the locking action on these couplers, eliminating dangling lanyards. All that is required for locking is a simple twist. The clips prevent the coupler from being unlocked until they are removed, providing a positive locking action.

The investment stainless steel cam arms on Boss-Lock cam & groove are guaranteed. We stand by our products before, during, and after the sale. In the event a cam arm is broken, return to Dixon for a free replacement. Contact sales@dixonvalve.com for assistance.

EZ Boss-Lock Cam & Groove

With the EZ Boss-Lock cam & groove couplings, there is no more fumbling with clamps, wire, clips, or pins. Simply close the handle and the locking mechanism is engaged. The ergonomic design makes the fittings easy to open with the release lever under your thumb.

EZ Boss-Lock cam & groove couplings are resistant to accidental disconnection when being dragged. The release lever opens in the direction opposite to the cam arm, so movement that can open the release lever also can close the cam arm. The rotating action helps keep the locking device free of debris. If the rotating lever is not flush with the handle, it is not properly engaged.

EZ Boss-Lock investment stainless steel cam arms offer the same benefits as Boss-Lock cam & groove. They can also be supplied with custom shanks and are available with swaged and phonographic finish (PF) shanks for hard-to-couple chemical hoses. Assemblies can be retrofitted onto undamaged stainless steel Boss-Lock couplings to protect your investment while upgrading.

EZLink® Armless Cam & Groove

EZLink Armless cam & groove are automatic, push-to-connect couplers providing a reliable connection. The low profile allows easy connection and disconnection in tight applications. The coupler tabs can be locked with safety pins and/or a zip tie, and cannot be pushed to disconnect when pressurized to 20 PSI or over.

Watch this short video to learn more about how to properly connect a Dixon EZLink Armless cam & groove.

The specifications for maximum working pressure and temperature vary depending on different factors.

Specifications:

- Maximum working pressure:

- 250 PSI (1-1/2″ and 2″), 150 PSI (3″ and 4″)

- Temperature range:

- Nitrile rubber gasket: 5°F (-15°C) to 180°F (82°C)

- Fluorosilicone gasket: -20°F (-29°C) to 180°F (82°C)

- FKM gasket: 40°F (4°C) to 200°F (93°C)

For a step-by-step look at how to replace the gasket in an EZLink Armless cam & groove, watch this video.

Vent-Lock® Safety Cam & Groove

These safety release cam & groove couplings permit the release of static pressure when disconnecting hose assemblies. The venting system protects the operator from being sprayed with hazardous or non-hazardous fluids or solids. Vent-Lock safety cam & groove feature safety orange cam arms. These couplings do not interchange with standard cam & groove products and are meant for use only with Vent-Lock L-style fittings.

Watch the video below to see how the Dixon Vent-Lock Safety Cam & Groove works.

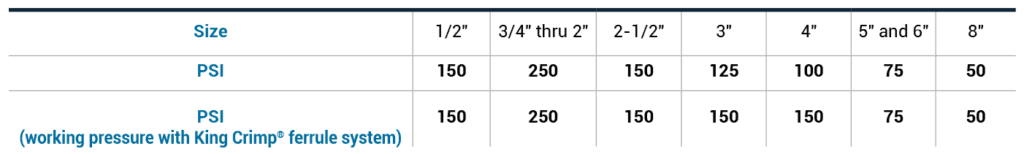

Vent-Lock safety cam & groove couplings are rated up to 250 PSI, depending on the size, as listed in the specifications below. This recommendation is based on the use of mating Dixon L-style fittings at an ambient temperature of 70°F (21°C) with a standard nitrile rubber seal installed. For use at elevated temperatures or other unusual operating conditions, contact Dixon.

Specifications

- 1″, 1-1/12″, and 2″ sizes have a maximum working pressure of 250 PSI

- 3″ size has a maximum working pressure of 150 PSI with King Crimp® ferrules, crimp sleeves, and bands at 125 PSI

- 4″ size has a maximum working pressure of 150 PSI with King Crimp ferrules, crimp sleeves, and bands at 100 PSI

Venting EZ Boss-Lock

Venting EZ Boss-Lock couplings feature EZLink tabs utilized as a secondary locking mechanism to capture the adapter in case of accidental uncoupling under pressure. The vent paths are designed to help control the direction of the venting media. EZ Boss-Lock cam arms are included for an additional level of safety. These couplings are compatible with standard cam & groove adapters, creating a viable option for a variety of applications.

Specifications on Dixon Cam & Groove

Dixon, Boss-Lock, and EZ Boss-Lock cam & groove couplers and adapters are produced to interchange with products produced to Commercial Item Description A-A-59326D. No standard exists for the 1/2″ and 8″ fittings, and generally, these sizes do not interchange with other manufacturers. Dust caps and dust plugs are not to be used in pressure applications for safety and environmental reasons.

Pressure Ratings

Pressure rating recommendations for Dixon, Boss-Lock, and EZ Boss-Lock are based on the use of mating Dixon fittings at ambient temperature 70°F (21°C) with standard nitrile rubber seal installed. For use at elevated temperatures or other unusual operating conditions, consult Dixon.