Understanding Sanitary Check Valves

Often overlooked but critical in function, check valves play a vital role in maintaining the efficiency, safety, and integrity of sanitary processes. Go with the flow as we delve into the details of the types and applications of sanitary check valves.

Overview

Check valves are installed in sanitary processes to allow flow in one direction and prevent backflow. The valves are mechanically operated and function automatically. This means manual, electric, or pneumatic actuation are not required to open and close the valve. Two types of check valves commonly used in sanitary applications are ball check valves and spring check valves.

Ball Check Valves

When liquid flows through a ball check valve, the ball is forced into the branch of the valve allowing full fluid flow. When the liquid stops, equalizing the pressure, the ball drops back into the seat, preventing backflow. Should reverse flow occur, the differential pressure will cause the ball to seal firmly against the seat preventing leakage.

Ball check valves are advantageous because they allow solids and viscous fluid to pass and have a low pressure drop. The ball in the check valve can be replaced when it wears rather than having to replace the entire valve. Since the ball moves during operation, the risk of impurities getting stuck to the ball is minimized, which makes the ball self-cleaning.

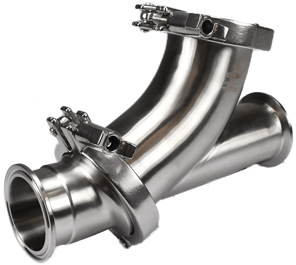

Dixon Y-Ball Check Valve

Dixon offers an HYC-series Y-ball check valve. This Y-ball check valve features a two-piece construction with a replaceable seat. The valve can be serviced in the field with no special tools required. Dixon’s Y-ball check valve has an operating temperature range of 15°F to 200°F (-9°C to 93°C), a maximum operating pressure of 150 PSI, and is available in 1-1/2” to 3” sizes.

Spring Check Valves

As the name suggests, a spring check valve is a type of check valve that uses a spring mechanism. When the flow stops or reverses, the spring pushes the valve plunger and seat against the valve body, preventing backflow. The spring also aids in closure under low head conditions maintaining a tight seal.

Spring check valves are reliable, easy to install, and require even less maintenance than ball check valves. Typically, the spring and the O-ring are the only parts that need to be replaced. Spring check valves also have the added benefit of vertical or horizontal installation depending on whether the valve is concentric or eccentric.

Concentric Spring Check Valves

The stem of a concentric spring check valve is aligned with the center of the seating surface. When the valve is open the disc remains centered along the flow path. The valve forms a tight seal when closed which ensures minimal leakage. Concentric spring check valves are used in vertical applications. The compact design is preferred where space is limited.

Eccentric Spring Check Valves

On an eccentric spring check valve, the downstream half of the valve body is level to allow full drainage of product after the valve is closed. Eccentric spring check valves are used in all non-vertical applications.

Dixon Spring Check Valves

Dixon offers EHSC-series and HSC-series spring check valves. Both series of spring check valves are designed to prevent reverse flow. The EHSC-series is an eccentric check valve that can be cleaned-in-place (CIP) in horizontal applications. The HSC-series is a concentric valve. It is also suited for CIP but in vertical applications only. Just like Dixon’s ball check valve, the EHSC-series and HSC-series spring check valves can be serviced in the field without any special tools. Available in 1/2” to 4” sizes, Dixon’s spring check valves have a temperature range of 15°F to 200°F (-9°C to 93°C) and a maximum operating pressure of 145 PSI.

Summary

Dixon Sanitary provides a variety of hygienic products for food processing, beverage, dairy, personal care, winery, brewery, pet products, and industrial markets. These products include, but are not limited to, check valves.

Both ball and spring check valves play an important role in keeping fluid moving in one direction. Knowing what type of check valve to use is important for safety and efficiency. Factors such as the application, material compatibility, flow rate and pressure, and maintenance and cleanability should be considered when choosing what check valve to use. At Dixon, we are committed to helping you find The Right Connection®. Contact us online or call 877.963.4966 for sanitary check valve recommendations for your specific application.