Pressure Reducing vs Pressure Restricting Valves

In the vast network of pipelines in industrial complexes, residential buildings, and municipal water systems, maintaining optimal pressure is crucial. Pressure control valves play a pivotal role in this process. Two common types of pressure control valves are pressure-reducing valves and pressure-restricting valves.

Pressure-Regulating Devices

The National Fire Protection Association (NFPA) defines pressure-regulating devices as something designed to reduce, regulate, control, or restrict water pressure. When installed as part of a hose valve the device is either a pressure-reducing valve or a pressure-restricting valve.

Pressure Reducing and Pressure Restricting

There are two terms to understand when discussing reducing and restricting devices: static and residual pressure. Static describes the pressure of water that is not flowing, meaning it is motionless. Residual pressure, however, describes the pressure of water when flowing or under working pressure.

Pressure-reducing valves are designed to reduce the downstream water pressure under both static and residual conditions. They are used in most fire suppression applications where the inlet pressure is greater than 175 PSI. These valves use a counteracting internal piston to use inlet pressure to reduce the outlet pressure. The larger the internal piston the greater the pressure-reducing capability.

Pressure-restricting valves are commonly found in the form of angle valves with preset orifices which restrict the volume of water, thereby lowering the pressure of the flowing water. They are designed to reduce the downstream water pressure under residual conditions only. Pressure-restricting valves are used when flowing water pressure needs to be controlled. NFPA requires restricting valves where the inlet pressure exceeds 100 PSI. Unlike pressure-reducing valves, restricting valves have no effect on the static pressure of a system.

Dixon® Pressure Reducing Valves

Dixon offers a variety of valves to support the fire protection market, including pressure-reducing valves.

Field Adjustable Pressure Reducing Valves: Angle and Straight

Features

- True combination shut-off and pressure-reducing valves

- 3/8” adjusting rod included

- Allows flexibility during installation with the ability to adjust settings once installed as hydraulic conditions change

- All shipped with installation manual and setting charts

- All “Made in the USA” using domestic cast brass

Specification

- 1/4” NPT gauge ports – both sides, drilled and tapped standard

Factory Set Pressure Reducing Brass Angle Valves: Female x Female and Female x Male, Angle Grooved x Grooved, Angle Grooved x Female

Features

- True combination shut-off and pressure-reducing valves

- Female x female valves have an open/closed indicator bonnet for confirmation of status

- Tamper-resistant and automatic

- Available with a tamper-proof switch

- All debris must be flushed from the system prior to being placed into service

- Internal check valve function

- All “Made in the USA” using domestic cast brass

- Available 1/4” NPT gauge ports

Specification

- 1-1/2” reduces inlet pressure of 300 PSI (2069 kPa) or less to working pressures of 10-175 PSI (69-1207 kPa); 2-1/2” reduced inlet pressures of 400 PSI (2758 kPa) or less to working pressures of 20-175 PSI (138-1207 kPa) under discharge or static conditions

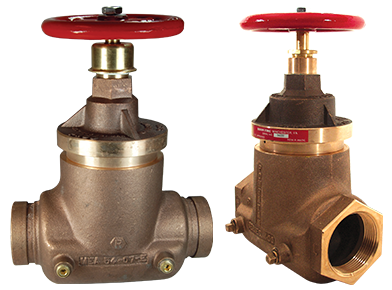

Factory Set Pressure Reducing Brass Globe Valves: Globe Female x Female, and Globe Grooved x Grooved

Features

- True combination shut-off and pressure-reducing valves

- Valves have an open/closed indicator bonnet for confirmation of status

- Available with a tamper-proof switch

- All “Made in the USA” using domestic cast brass

- Internal check valve function

Specifications

- 2-1/2” size reduces inlet pressures of 400 PSI (2758 kPa) or less to desired working pressures from 20-175 PSI (138-1207 kPa) under discharge or static conditions

- 1/4” NPT gauge ports – both sides, drilled, and tapped standard

Dixon Pressure Restricting Valves

Dixon also offers pressure-restricting valves to ensure you always have The Right Connection®.

Adjustable Pressure-Restricting Device

- Device restricts pressure in the piping system to such a degree that the hose lines can be handled by persons untrained in the handling of heavy fire streams

- Intended to be used in conjunction with standard angle valves

- All “Made in the USA” using domestic cast brass

- 1-1/2” and 2-1/2” options

Specification

- Working pressure: 175 PSI at 70°F (21°C)

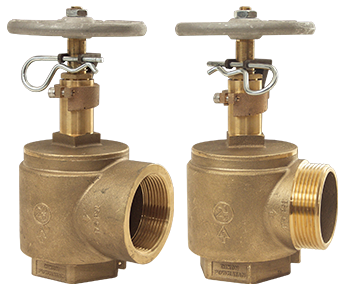

Domestic Adjustable Pressure-Restricting Angle Valves: Female Outlet and Male Outlet

Features

- Restricting devices can be manually bypassed if required by opening the valve fully: pull the pin allowing the yoke to fall back from the valve stem, which allows the valve to be fully opened. When the valve needs to be restricted again, slide the yoke back into place to be NFPA-compliant

- All “Made in the USA” using domestic cast brass

- 1-1/2” and 2-1/2” options

Specification

- Restricts inlet pressure from 70 PSI up to a maximum of 175 PSI

Global Adjustable Pressure-Restricting Angle Valves: Female Outlet and Male Outlet

Features

- Restricting valve does not affect the static pressure of a system

- Restricting devices can be manually bypassed if required by opening the valve fully: pull the pin allowing the yoke to fall back from the valve stem, which allows the valve to be fully opened. When the valve needs to be restricted again, slide the yoke back into place to be NFPA compliant

- 1-1/2” and 2-1/2” options

Specification

- Preset orifices restrict the volume of water, thereby lowering the pressure of the flowing water; NFPA requires restricting valves where inlet pressure exceeds 100 PSI

Summary

Both pressure-reducing and pressure-restricting valves play vital roles in regulating fluid pressure within a system. While pressure-reducing valves ensure a consistent downstream pressure by reducing the incoming pressure, restricting valves focus on limiting maximum pressure to prevent over-pressurization. Understanding the distinct functions and applications of these valves is essential for designing and using efficient and safe fluid control systems.

For more information visit dixonvalve.com or call 877.963.4966 for recommendations on your specific application.