Proper NPT Threads Installation

History

The onset of the industrial revolution increased the need for the standardization of screw threads. As new manufacturing processes emerged it became obvious just how many different types of threads existed. This caused compatibility issues between different manufacturers and users.

In 1841, Sir Joseph Whitworth, an English engineer and inventor created a uniform threading system to address the issue. His thread form was based on a 55-degree thread angle with rounded roots and crests. This became a widely accepted standard for connecting thread for pipes and became known as the British Standard Pipe thread (BSP).

BSP threads were often used in the United States and Canada through the 1860s, but they were never universally accepted, so the lack of compatibility and need for standardization remained. In 1864, William Sellers, an American engineer, proposed a new set of standards for bolts, screws, and nuts. His design featured a 60-degree angle with flattened peaks and valleys that was easier to manufacture and produce. Sellers’ design, known as National Pipe Tapered (NPT) threads, gained widespread acceptance and played a vital role in the American industrial revolution. NPT threads were eventually adopted as the national standard in the U.S.

NPT and NPTF Threads

As indicated in the name, NPT threads are tapered, which means the threads decrease in diameter over the length of the threads. This differs from parallel or straight threads where the diameter stays the same. Additionally, tapered threads can create a seal on their own, whereas straight threads hold the connection together but require a gasket or O-ring for sealing.

To dive deeper into the basics of threads, check out this blog post: Threads 101.

It is important not to confuse NPT threads with NPTF threads. NPTF stands for National Pipe Taper Fuel. While NPT and NPTF threads are identical in appearance, the way they create leak-resistant seals is different.

There is a slight clearance between the roots and crests of NPT threads. This creates a spiral leak path along the male thread crests. A thread sealant is required to prevent leaks. NPTF threads, however, do not require a sealant.

Paste or PTFE tape can be used as a sealant. The type of PTFE tape depends on the application. Dixon offers the following types of PTFE tape:

● Industrial Heavy Duty PTFE tape

● Industrial PTFE tape

● Stainless steel PTFE tape

● PTFE tape for LP gas

● American Made PTFE tape

Safety note: These PTFE tapes are not intended for use in oxygen applications.

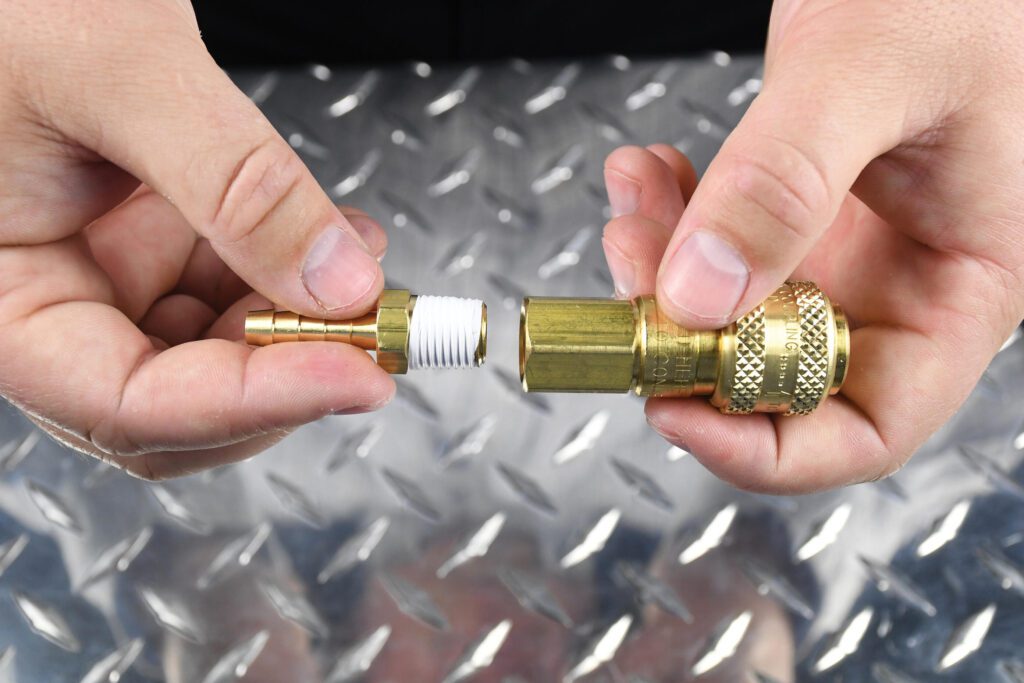

How to Use PTFE Tape

The seal on NPT threads is created by the metal-to-metal contact between the roots and crests of the male and female threads. Using too much PTFE tape or pairing liquid sealant with PTFE tape may cause distortion, poor thread engagement, or cracking of the coupling during assembly.

The total number of threads engaged should be between 3-1/2 to 6. Any number of threads outside of this range may indicate over or under-tightening, or out-of-tolerance threads.

After assembling an NPT thread connection, always proof-test the connection before operating the system. This is done by pressurizing the unit to 150% of the working pressure in an enclosed/protective environment. If the joint proved to be inadequately tightened during proof-pressure testing, tighten it further in 1/8 turn increments until a reliable seal is attained. Do not exceed 3 turns from finger tight.

Safety

All couplings should be viewed as potential hazards that can cause property damage, personal injury, or even death if used or installed improperly. Improper use includes selecting a product unsuitable for your application, installing or using the product incorrectly, and/or ignoring signs of imminent failure or misuse. Failure may result in explosive propulsion of components, rapid expulsion of hazardous media, and failure or unintentional movement of a fluid-powered component.

Couplings should be installed in a location that will allow easy operation of the coupling and accessibility for all necessary installation tools. Care should be given to consider operator safety, especially if spillage upon disconnect could result in fluid ignition or skin and eye irritation.

Only apply wrenches to the hex or machined wrench flats that are provided for assembly purposes, nowhere else. Never clamp on the sleeve of the coupler or the nose of the plug as this will cause distortion and/or damage.

SOURCE: https://blog.dixonvalve.com/proper-npt-threads-installation